x

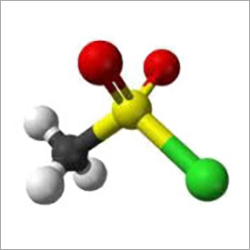

Methane Sulfonyl Chloride

1 INR/Kilograms

Product Details:

- Smell Pungent, irritating odor

- Physical Form Liquid

- EINECS No 204-708-2

- Purity 99%

- Usage Used for preparing sulfonamides, and as alkylating or chlorinating agent

- Molecular Weight 114.55 g/mol

- Molecular Formula CH3SO2Cl

- Click to View more

X

Methane Sulfonyl Chloride Price And Quantity

- 1 Kilograms

- 1 INR/Kilograms

Methane Sulfonyl Chloride Product Specifications

- Store in tightly closed container, cool, dry, well-ventilated area, away from moisture

- 24 Months

- Methane Sulfonyl Chloride

- 1.480 Gram per cubic centimeter(g/cm3)

- n20/D 1.441

- <1 (strongly acidic)

- 124-63-0

- CH3SO2Cl

- 114.55 g/mol

- 204-708-2

- 99%

- Used for preparing sulfonamides, and as alkylating or chlorinating agent

- Pungent, irritating odor

- Liquid

- -32 C

- Pungent

- Reacts with water; soluble in organic solvents like chloroform, benzene

- Chemical Compound

- Intermediate in organic synthesis, pharmaceuticals, agrochemicals, dyes

- Liquid form

- CH3SO2Cl

- Clear to pale yellow

- YES

- Colorless to pale yellow liquid, highly reactive, lachrymatory compound, moisture sensitive

- Industrial Grade

- 29049090

Methane Sulfonyl Chloride Trade Information

- 25 Kilograms Per Week

- 3-4 Week

Product Description

Methane Sulfonyl Chloride

| Analysis Item | Specification |

|---|---|

| Purity % | 99.5 Min% |

| Appearance | Clear Colourless Transparent Liquid |

| Color (APHA) | 50 Max |

| Water Content (ppm) | 200 Max |

| Heavy Metal (mg/kg) | 5 ppm Max |

| Fe 3+ (mg /kg) | 5 ppm Max |

| Density (18/4oC) | 1.480-1.482 |

| Chloride (mg/kg) | 20 ppm Max |

Applications of Methane Sulfonyl Chloride

- Methane Sulfonyl Chloride finds application in Pharmaceutical & Agrochemical synthesis.

- It also finds application and Dyes Manufacturing.

- The main use of Methanesulfonyl chloride is the formation of Methanesulfonates from alcohols in the presence of a non-nucleophilic base. Methanesulfonates are used as intermediates in substitution reactions, elimination reactions, reductions, and rearrangement reactions.

- When treated with a Lewis acid, oxime methanesulfonates will undergo a facile Beckmann rearrangement.

Applications and Benefits

Methane Sulfonyl Chloride plays a critical role in the chemical industry as an intermediate for pharmaceuticals, agrochemicals, and dyes. Its ability to act as a sulfonylating and chlorinating agent makes it indispensable in organic synthesis, enabling the preparation of sulfonamides and facilitating various laboratory-scale and industrial reactions. Its high purity ensures reliable and efficient performance in targeted chemical transformations.

Safe Storage and Handling

To maintain stability, Methane Sulfonyl Chloride should be stored in tightly closed containers made of HDPE in cool, dry, and well-ventilated spaces, and always away from moisture or incompatible materials like water, strong bases, or amines. Personal protective equipment (PPE) is essential when handling to prevent inhalation or contact with skin and eyes. Good safety practices and adherence to recommended guidelines ensure its safe use.

FAQs of Methane Sulfonyl Chloride:

Q: How should Methane Sulfonyl Chloride be safely stored and handled?

A: Store Methane Sulfonyl Chloride in tightly closed HDPE containers, placed in a cool, dry, well-ventilated area, away from moisture, water, alcohols, amines, and strong bases. Always wear appropriate personal protective equipment (PPE), including gloves and goggles, and avoid inhalation or direct contact with skin and eyes due to its corrosive and toxic nature.Q: What are the main industrial uses of Methane Sulfonyl Chloride?

A: Methane Sulfonyl Chloride is commonly used as an intermediate in organic synthesis for pharmaceuticals, agrochemicals, and dyes. It serves as a key reagent for preparing sulfonamides and is employed as an alkylating or chlorinating agent in a wide range of chemical and industrial processes.Q: When is the best time to use Methane Sulfonyl Chloride in chemical synthesis?

A: Use Methane Sulfonyl Chloride during the sulfonylation or chlorination steps in the synthesis of desired compounds when a high-purity, stable, and reactive sulfonylating agent is required. It is particularly useful in controlled environments where moisture exposure can be minimized.Q: Where can Methane Sulfonyl Chloride be transported or shipped?

A: Methane Sulfonyl Chloride can be shipped domestically or internationally according to ADR/RID, IMDG, and IATA guidelines for hazardous goods. Its packaging (usually in 250 kg HDPE drums) and labeling must comply with regulatory requirements due to its hazardous, corrosive classification (UN 3246).Q: What is the process for handling accidental exposure to Methane Sulfonyl Chloride?

A: In case of accidental exposure, immediately move the affected person to fresh air. For skin or eye contact, flush thoroughly with plenty of water and seek medical attention. Avoid ingesting the chemical, and ensure all spills are managed with proper containment and cleanup using appropriate PPE.Q: What benefits does Methane Sulfonyl Chloride provide in pharmaceutical manufacturing?

A: This compound enables efficient generation of sulfonamides, a crucial class of pharmaceuticals, by acting as a selective sulfonylating agent. Its high reactivity and purity contribute to more streamlined and effective synthesis pathways, supporting product quality and process efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Speciality Chemical' category

|

SHILPA CHEMSPEC INTERNATIONAL PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |