x

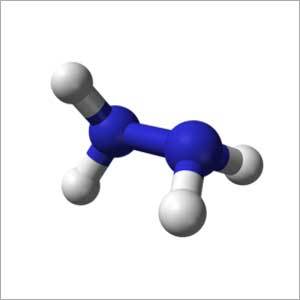

Hydrazine Hydrate

1 INR/Kilograms

Product Details:

- Shelf Life 12 months

- Application Oxygen scavenger in boiler feedwater, blowing agent, chemical synthesis, polymerization, pharmaceuticals, water treatment

- Molecular Weight 50.06 g/mol

- Poisonous Yes, toxic

- Refractive Rate 1.4183

- Physical Form Liquid

- CAS No 7803-57-8

- Click to View more

X

Hydrazine Hydrate Price And Quantity

- 1 Kilograms

- 1 INR/Kilograms

Hydrazine Hydrate Product Specifications

- N2H4H2O

- -51 C

- 206-114-9

- 1.03 Gram per cubic centimeter(g/cm3)

- H2N-NH2H2O

- 28251090

- 80% Min

- Amorphous

- Hydrazine monohydrate, Water

- Highly reactive base, strong reducing agent, volatile, colorless, water-soluble

- Clear, colorless liquid

- Industrial Grade

- Ammonia-like, pungent odor

- 7803-57-8

- Liquid

- 1.4183

- Yes, toxic

- 50.06 g/mol

- Oxygen scavenger in boiler feedwater, blowing agent, chemical synthesis, polymerization, pharmaceuticals, water treatment

- 12 months

- Alkaline (about 10-11)

- Store tightly closed in a cool, dry, well-ventilated area away from heat, sparks, and open flame

- Industrial and research applications only

- Hydrazine Compound

- Miscible with water, alcohol, and ether

Hydrazine Hydrate Trade Information

- 25 Kilograms Per Week

- 3-4 Week

- All India

Product Description

Hydrazine Hydrate 80% (HH)

| Inspection method/Characterstic | Result | Specification | Unit |

|---|---|---|---|

| Clear,colourless liquid | Complies | Complies |

|

| 64/Q2010/HBL-05/10px N2H4*H2O N2H4 | 80,4 | 79,7 80,79 | % |

| 64/q2080/HBL-D6/10px CI- SO4 | 3 | <=12 | mg/kg |

| 64/q2080/HBL-92/5 fe | 0.2 | <=0.4 | mg/kg |

Industrial Application & Utility

Hydrazine Hydrate finds extensive utility as an oxygen scavenger, blowing agent, and reducing agent in chemical synthesis and polymerization. Its compatibility with water, alcohol, and ether enables diverse applications, notably in pharmaceutical and water treatment industries. Manufacturers, distributors, and suppliers in India ensure reliable delivery of this industrial-grade compound for research and specialized uses.

Safety, Storage & Regulatory Compliance

Given its classification under Hazard Class 6.1 (toxic substances), Hydrazine Hydrate requires careful handling and storage in cool, dry, well-ventilated areas, away from heat, sparks, and flames. Packaging uses sturdy containers such as HDPE drums and IBC tanks. Transport is strictly regulated following ADR/RID, IMDG, and ICAO/IATA guidelines to mitigate risk and comply with legal standards.

Environmental & Health Precautions

Exposure to Hydrazine Hydrate can result in serious health hazards through inhalation, ingestion, or skin contact. Immediate medical attention is advised in case of exposure. The compound is highly toxic to aquatic life; environmental release must be avoided. Decomposition may produce ammonia and nitrogen oxides, underscoring the importance of managing incompatibilities with oxidizers, acids, and heavy metal salts.

FAQs of Hydrazine Hydrate:

Q: How should Hydrazine Hydrate be stored to maintain stability and safety?

A: Hydrazine Hydrate should be stored tightly closed in a cool, dry, and well-ventilated area away from direct heat, sparks, and open flames. Appropriate containers such as HDPE drums or IBC tanks are recommended to ensure stability and reduce the risk of hazardous incidents.Q: What are the primary industrial uses of Hydrazine Hydrate?

A: Hydrazine Hydrate is widely used as an oxygen scavenger in boiler feedwater, blowing agent for foaming plastics, and as a strong reducing agent in chemical synthesis, polymerization, water treatment, and pharmaceutical manufacturing. Its reactivity enables diverse chemical applications in industry and research.Q: When is immediate medical attention required for Hydrazine Hydrate exposure?

A: Immediate medical attention is necessary if Hydrazine Hydrate is inhaled, ingested, or comes into contact with skin or eyes. The substance is highly toxic and can cause severe health effects, necessitating prompt intervention and specialized treatment.Q: Where is Hydrazine Hydrate commonly supplied and distributed in India?

A: Hydrazine Hydrate is distributed by manufacturers, importers, suppliers, and traders across India, using robust packaging such as HDPE drums and IBC tanks to ensure safe transport and storage for industrial and research sectors.Q: What processes should be implemented for safe handling and transport of Hydrazine Hydrate?

A: Safe handling includes using personal protective equipment, storing away from incompatible materials like strong oxidizers and acids, and adhering to established transport regulations such as ADR/RID, IMDG, and ICAO/IATA to minimize health and environmental risks.Q: What are the environmental hazards associated with Hydrazine Hydrate?

A: Hydrazine Hydrate is very toxic to aquatic life and can cause significant environmental harm. Strict protocols must be followed to prevent spills or improper disposal, including containment measures, prompt cleanup, and disposal according to hazardous waste regulations.Q: What benefits does Hydrazine Hydrate provide in industrial applications?

A: Hydrazine Hydrates strong reducing properties and ability to act as an oxygen scavenger enhance efficiency in boiler systems, chemical synthesis, and polymer manufacturing, contributing to improved process control, product quality, and system longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

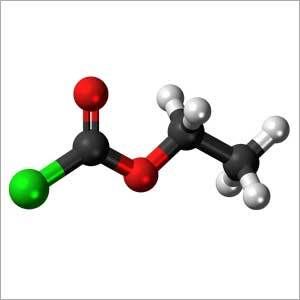

Other Products in 'Speciality Chemical' category

|

SHILPA CHEMSPEC INTERNATIONAL PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |