x

Diethyl Malonate (DEM)

1 INR/Kilograms

Product Details:

- Physical Form Liquid

- Taste Characteristic, fruity

- Melting Point -51 C

- Properties Colorless, clear liquid; fruity odor; miscible with most organic solvents; slightly soluble in water

- EINECS No 203-305-9

- Shelf Life 24 months in recommended storage conditions

- CAS No 105-53-3

- Click to View more

X

Diethyl Malonate (DEM) Price And Quantity

- 1 INR/Kilograms

- 1 Kilograms

Diethyl Malonate (DEM) Product Specifications

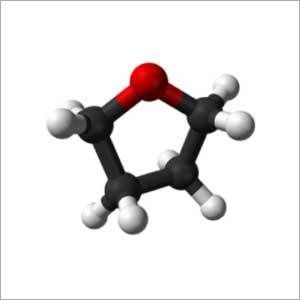

- Diethyl Malonate

- CH2(COOC2H5)2

- Used in the manufacture of barbiturates, vitamin B1, perfumes, and agricultural chemicals

- 160.17 g/mol

- 29171990

- Fruity odor

- Pharmaceutical intermediates, organic synthesis, agrochemicals

- n20/D 1.415

- Transparent liquid

- C7H12O4

- Slightly soluble in water; soluble in alcohol and ether

- Keep in tightly closed containers, store in cool, dry, well-ventilated area away from incompatible materials

- Tech / Pharma / AR Grade

- 99%

- Neutral

- Non-poisonous

- Organic Chemical

- Liquid

- Characteristic, fruity

- -51 C

- Colorless, clear liquid; fruity odor; miscible with most organic solvents; slightly soluble in water

- 24 months in recommended storage conditions

- 203-305-9

- 105-53-3

- 1.041 Gram per cubic centimeter(g/cm3)

Diethyl Malonate (DEM) Trade Information

- 25 Kilograms Per Week

- 3-4 Week

Product Description

Diethyl Malonate (DEM)

| Commodity Name | Diethyl malonate | |

|---|---|---|

| Testing item | Unit | Specification |

| appearance |

| Colorless transparent liquid |

| Chromaticity | Hazen | 20max |

| Purity(By G.C) | % | 99.60min |

| Water | % | 0.050max |

| Acidity | % | 0.010max |

| Result |

|

|

Applications of Diethyl Malonate (DEM)

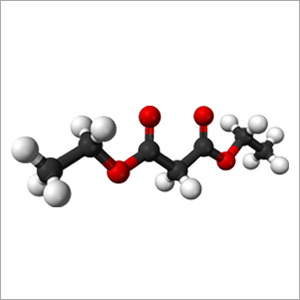

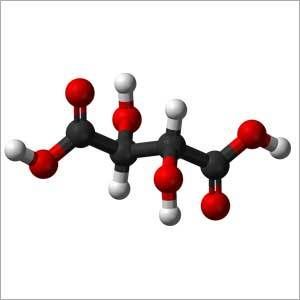

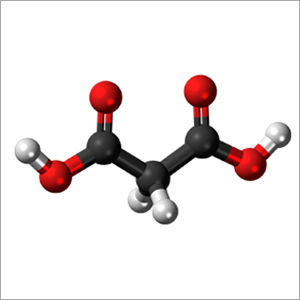

Diethyl malonate, also known as DEM, is the diethyl ester of malonic acid. It is used in perfumes & Pharmaceuticals & Vitamins manufacturing.

Key Physical and Chemical Properties

Diethyl Malonate features a neutral pH, high purity, and a transparent appearance. The compound boasts a molecular weight of 160.17 g/mol and a density of 1.041 g/cm. It displays low vapor pressure and moderate viscosity at room temperature. Its autoignition temperature of 380C enhances handling safety, while its refractive rate of n20/D 1.415 supports analytical applications. Slight water solubility and full miscibility with alcohol and ether enables versatile application across industries.

Versatile Applications in Industry

Used extensively in pharmaceuticals for the production of intermediates, Diethyl Malonate is crucial in the synthesis of barbiturates, vitamin B1, agrochemicals, and fragrance compounds. Its chemical stability ensures reliability in processes requiring precise reactants. Manufacturers, suppliers, and distributors in India offer DEM in various grades and convenient packaging, making it accessible for different usage scales and purity requirements.

Safe Handling and Storage Guidelines

Diethyl Malonate remains stable when stored in tightly closed containers, in cool, dry, well-ventilated spaces away from incompatible materials. It is non-hazardous for transport and non-poisonous, minimizing risks during handling and logistics. Recommended storage ensures optimal shelf life up to 24 months, preserving its chemical integrity for industrial and laboratory use.

FAQs of Diethyl Malonate (DEM):

Q: How should Diethyl Malonate be stored to maintain its stability and shelf life?

A: DEM should be kept in tightly closed containers and stored in cool, dry, well-ventilated areas away from incompatible materials. Proper storage ensures its stability and a shelf life of up to 24 months.Q: What are the main uses and benefits of Diethyl Malonate in industrial applications?

A: Diethyl Malonate is primarily used in the production of pharmaceutical intermediates, barbiturates, vitamin B1, perfumes, and agrochemicals. Its high purity, stability, and compatibility with organic solvents make it valuable for precise synthesis and formulation.Q: Where can Diethyl Malonate be sourced and in what packaging forms?

A: DEM is available through distributors, importers, manufacturers, and suppliers in India. Packaging options include HDPE drums, glass bottles, and bulk containers, catering to different batch sizes and storage preferences.Q: What is the process for handling Diethyl Malonate safely during transport and use?

A: Due to its non-hazardous classification for transport, DEM can be handled without special precautions. However, general chemical safety measuressuch as proper labeling, using sealed containers, and avoiding exposure to incompatible substancesare advised.Q: When is Diethyl Malonate preferred in reaction processes?

A: DEM is favored when high purity and chemical stability are critical, such as in the synthesis of pharmaceuticals and fine chemicals. Its reactivity and miscibility with organic solvents enhance its effectiveness in controlled reactions.Q: What is the recommended method for utilizing Diethyl Malonate in organic synthesis?

A: For organic synthesis, DEM is typically introduced as an intermediate reactant. Its miscibility with most organic solvents allows for straightforward integration into reaction mixtures, facilitating manufacture of complex compounds like barbiturates and vitamins.Q: What are the advantages of choosing Diethyl Malonate for manufacturing applications?

A: Diethyl Malonate offers consistent chemical stability, high purity (99%), non-poisonous properties, and logistic convenience. These factors collectively reduce risk and improve product yield in pharmaceutical, perfume, and agrochemical production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Speciality Chemical' category

|

SHILPA CHEMSPEC INTERNATIONAL PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |